Grad

ISO

Dichte(g/cm3)TRS

(N/mm2)Geschirr(HRA)

AnwendungenYG11CK40

14.35

87,6

Form- oder Prägematrizen für Metallpulver und Nichtmetallpulver.YG15

K40

14.0

YG18CK40

13.5Für verschiedene Matrizen, die durch Kaltschmieden, Kaltprägen und Warmschmieden hergestellt werden.

YG20C

K0515.1

die Schlicht- und Vorschlichtbearbeitung von Gusseisen und Nichteisenmetallen sowie für die Bearbeitung von Manganstahl und gehärtetem StahlYM6

K15

114.889,5

2YW2M20

391,5Geeignet zum Schlichten und Vorschlichten von Stahl und Stahlguss mit mäßigem Vorschub und eher hoher Schnittgeschwindigkeit

4YT5P30

5Q1. Sind Sie Hersteller oder Handelsunternehmen?A: Wir sind Hersteller von Wolframkarbidprodukten. und wir haben unsere Ausrüstung für die Herstellung von Hardware-Werkzeugen erweitert.

Q2. Ist der Preis wettbewerbsfähig?

6(Sie können unseren Verkäufer auch direkt per E-Mail / Skype / Whats App kontaktieren)2. Innerhalb von 24 Stunden Feedback nach Erhalt Ihrer Nachricht.

F5: Wie können wir Ihrem Unternehmen vertrauen?

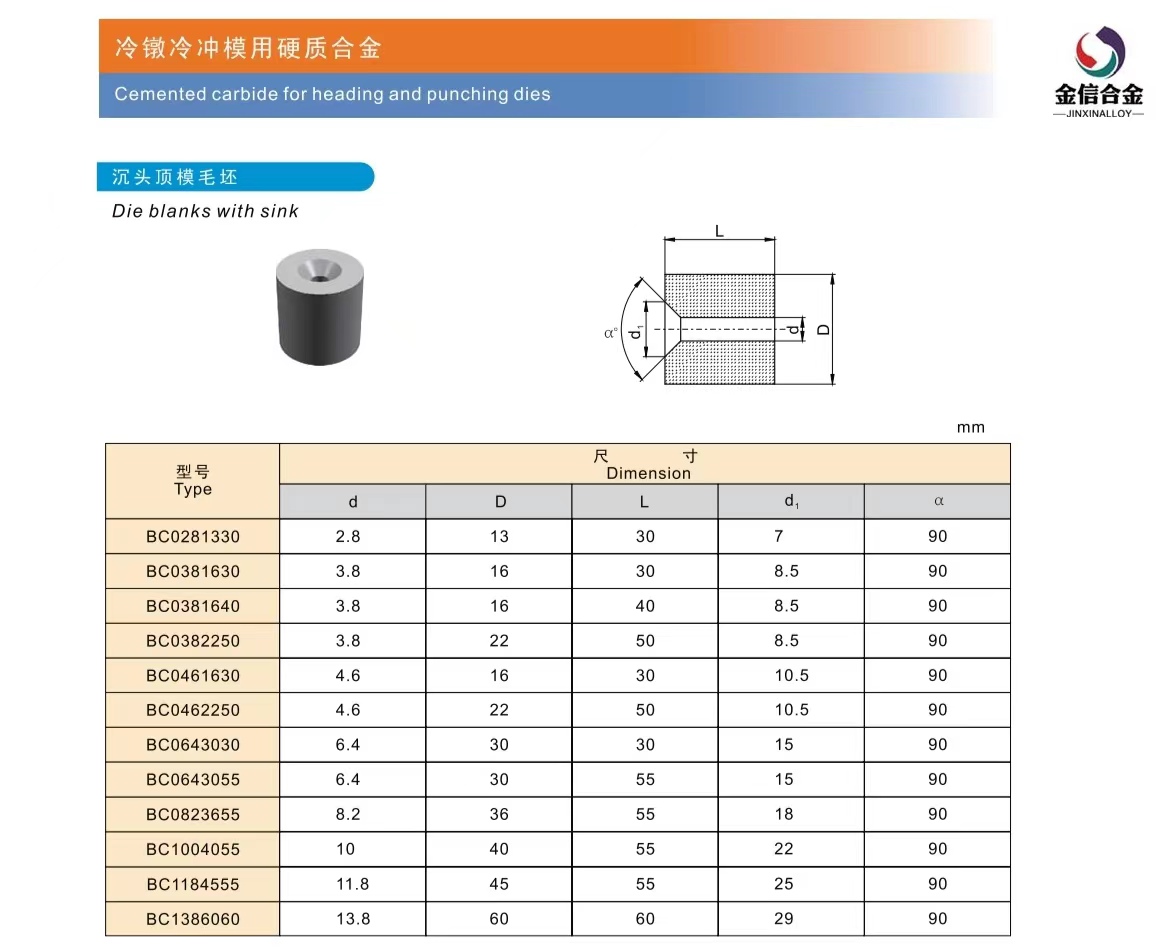

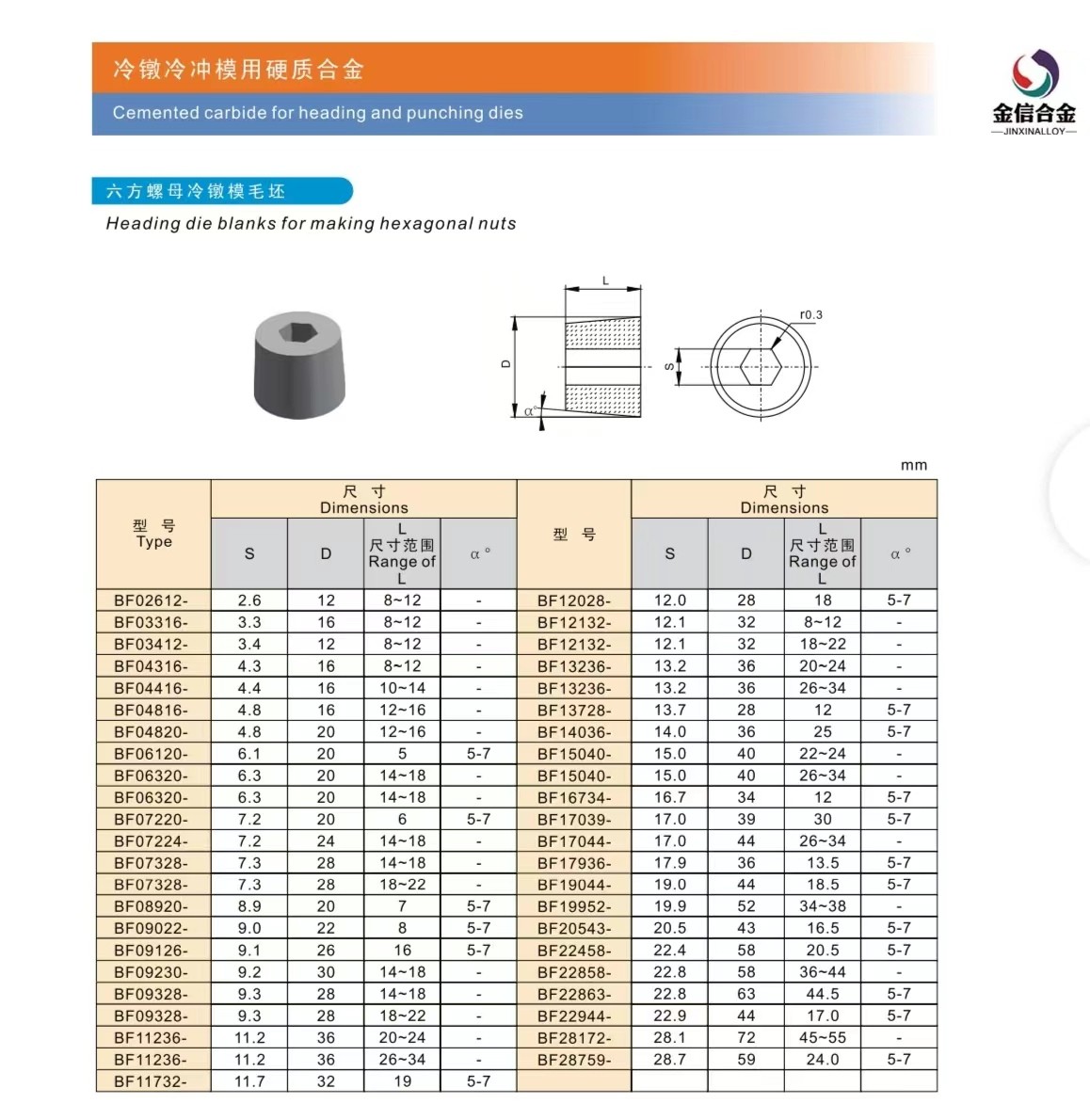

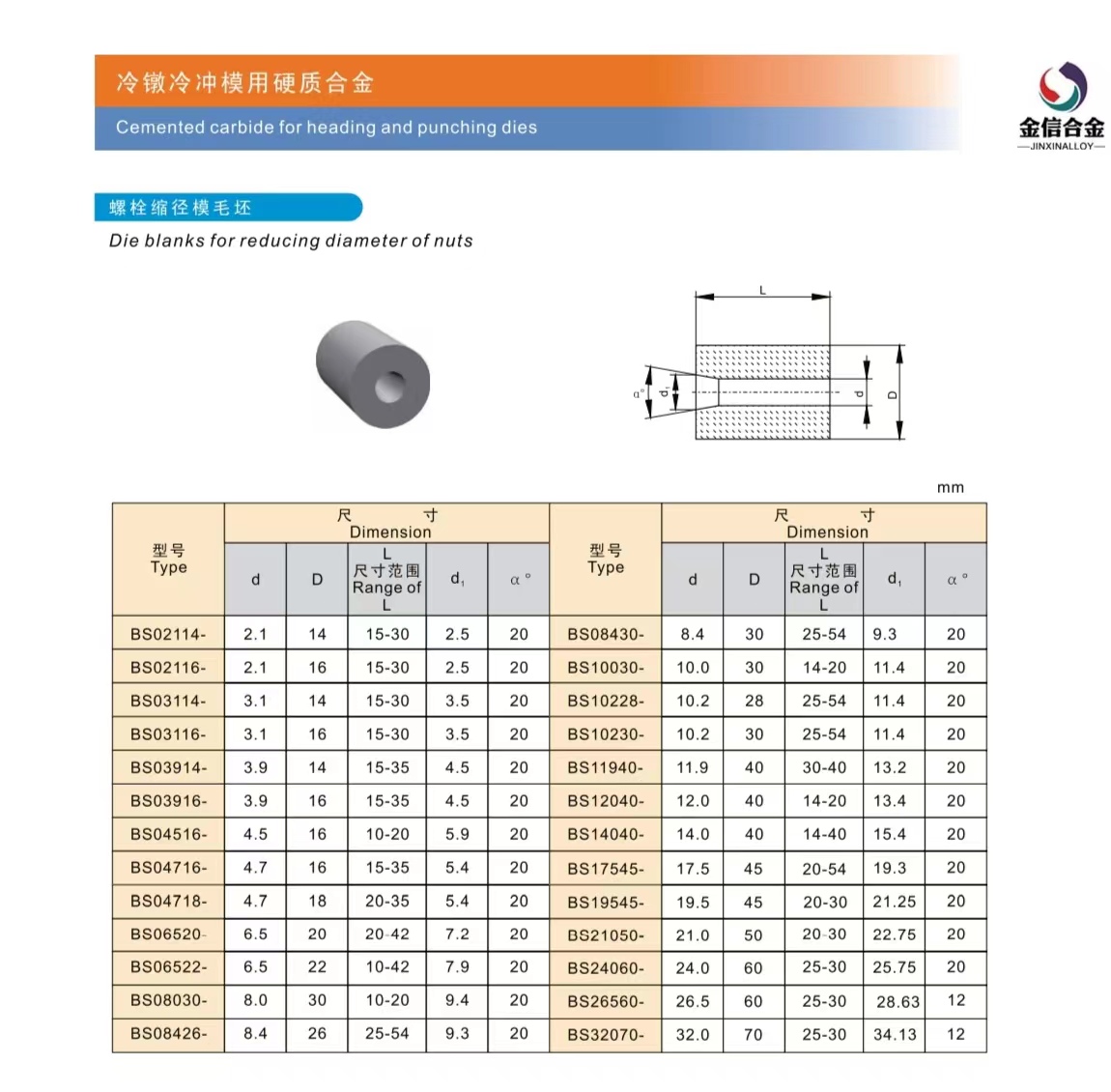

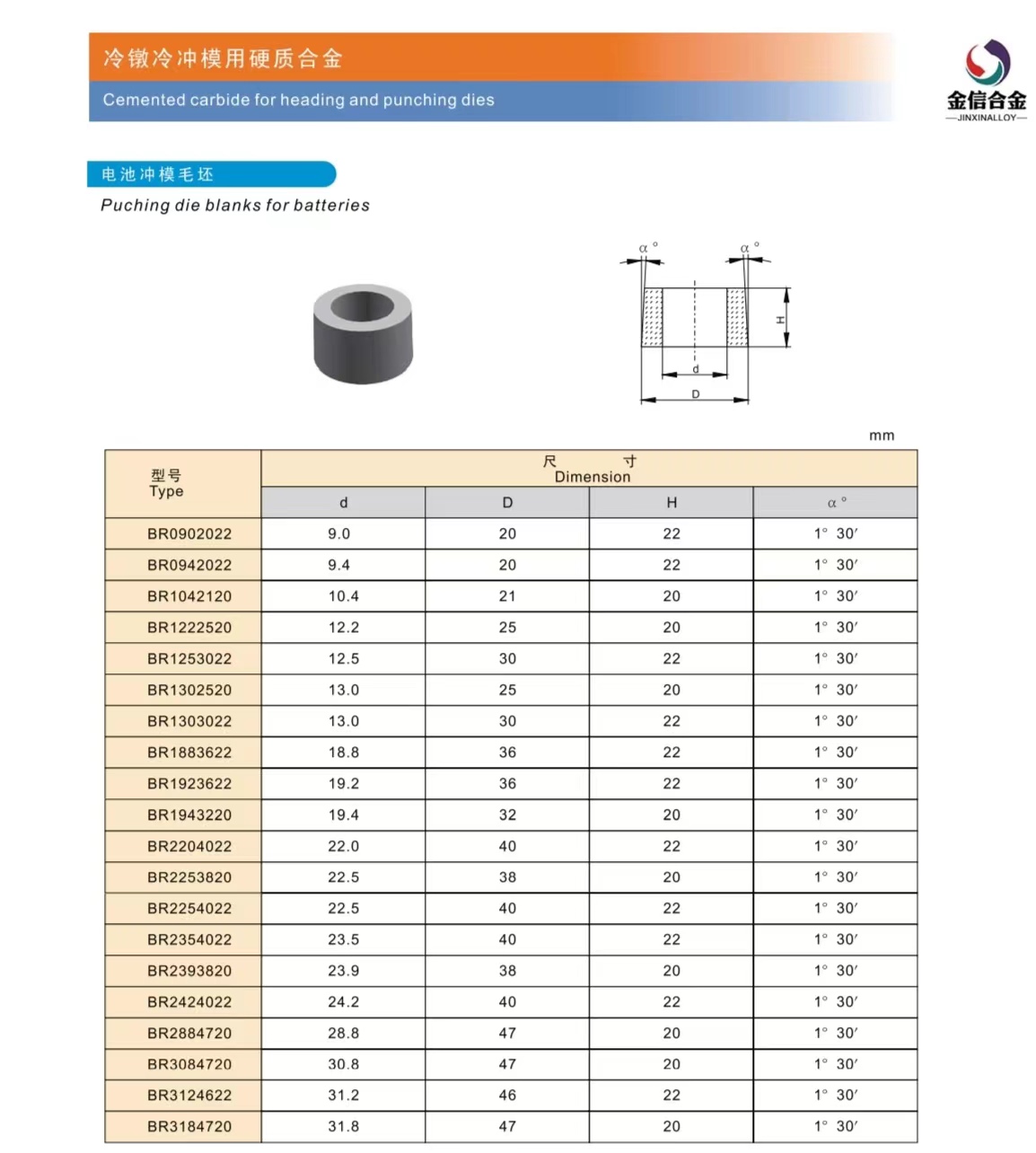

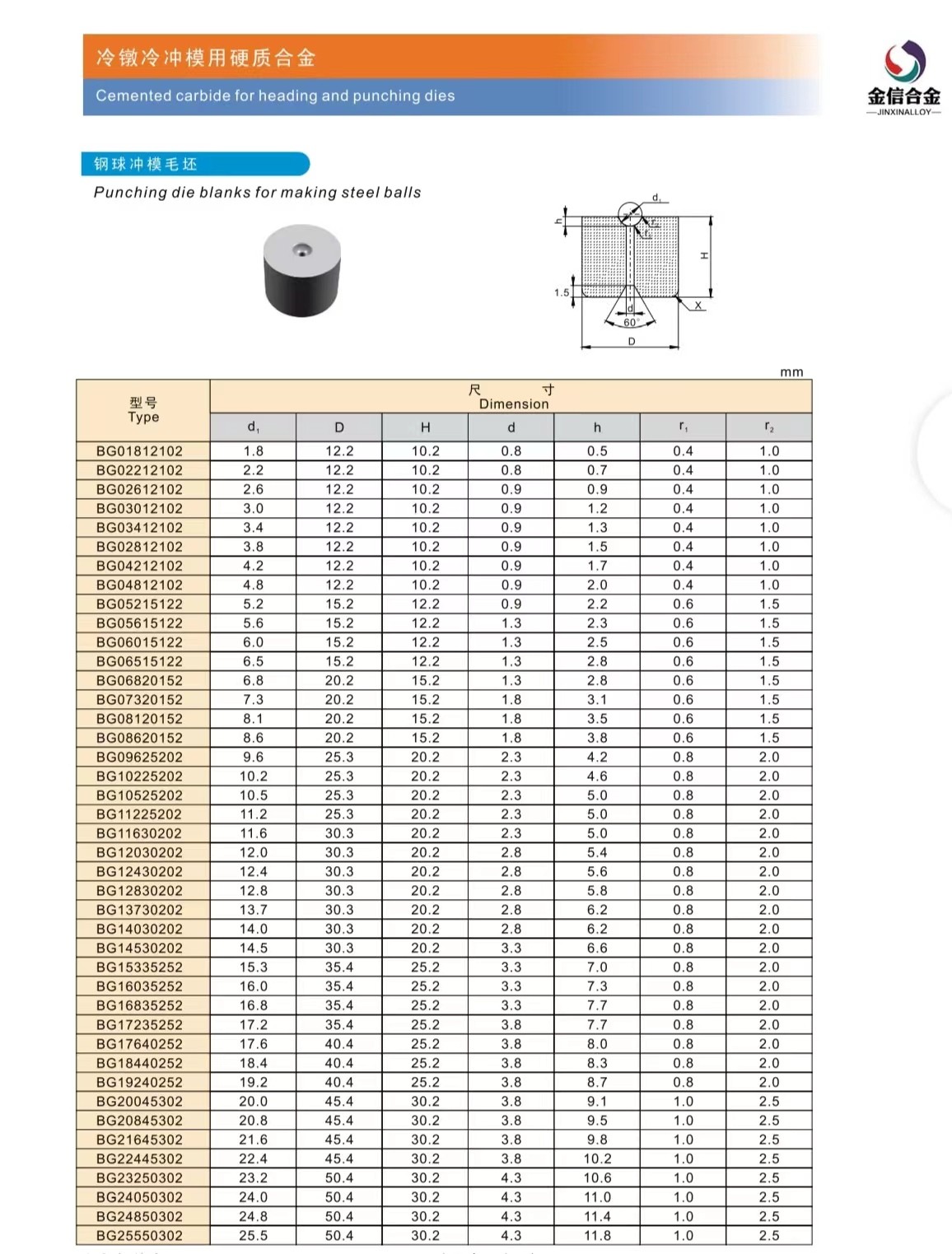

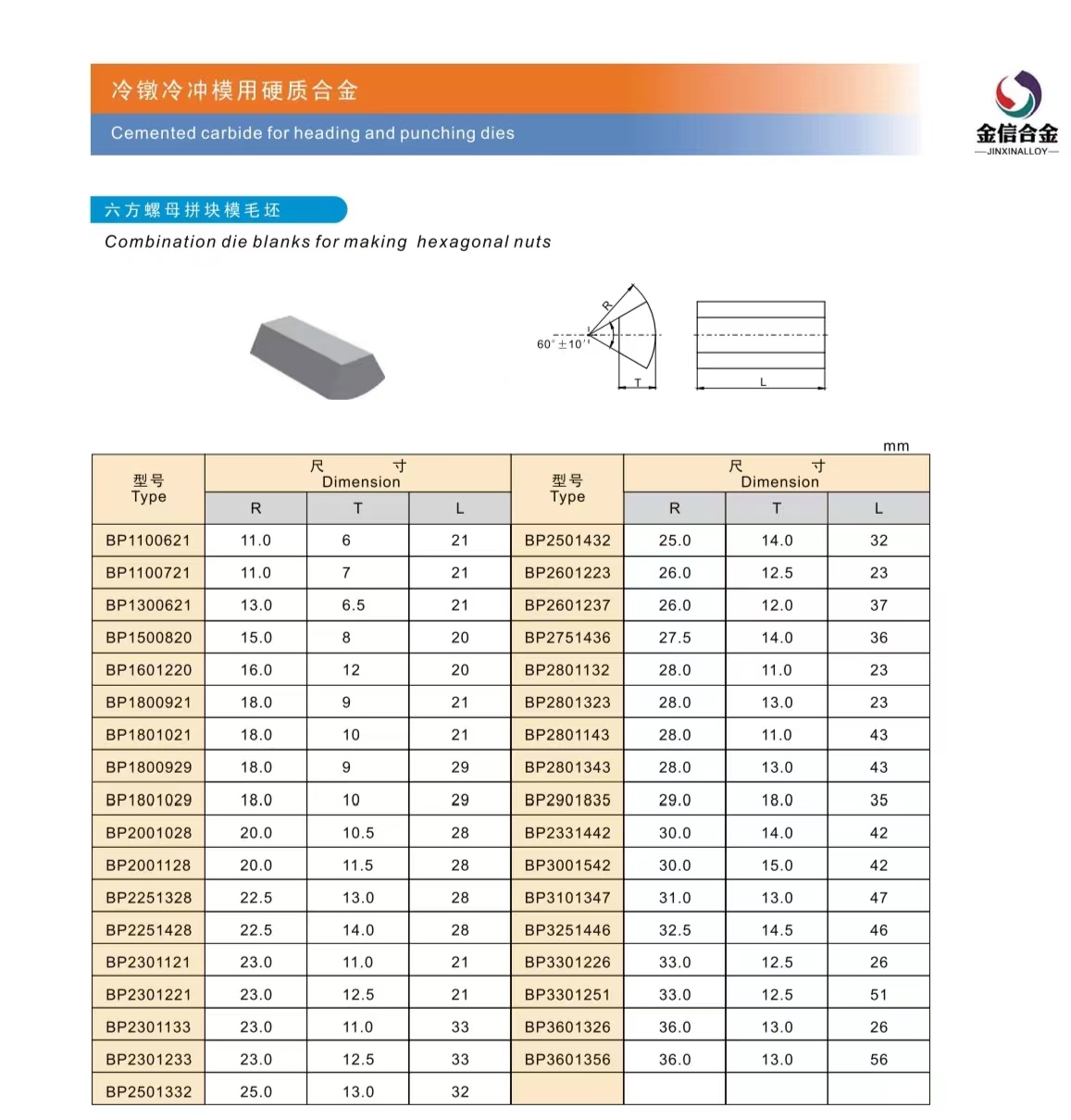

7die Vorauszahlung. In addition, there are some special types of molds, such as hexagonal molds, spiral molds and other non-standard molds etc.

Product Paramenters

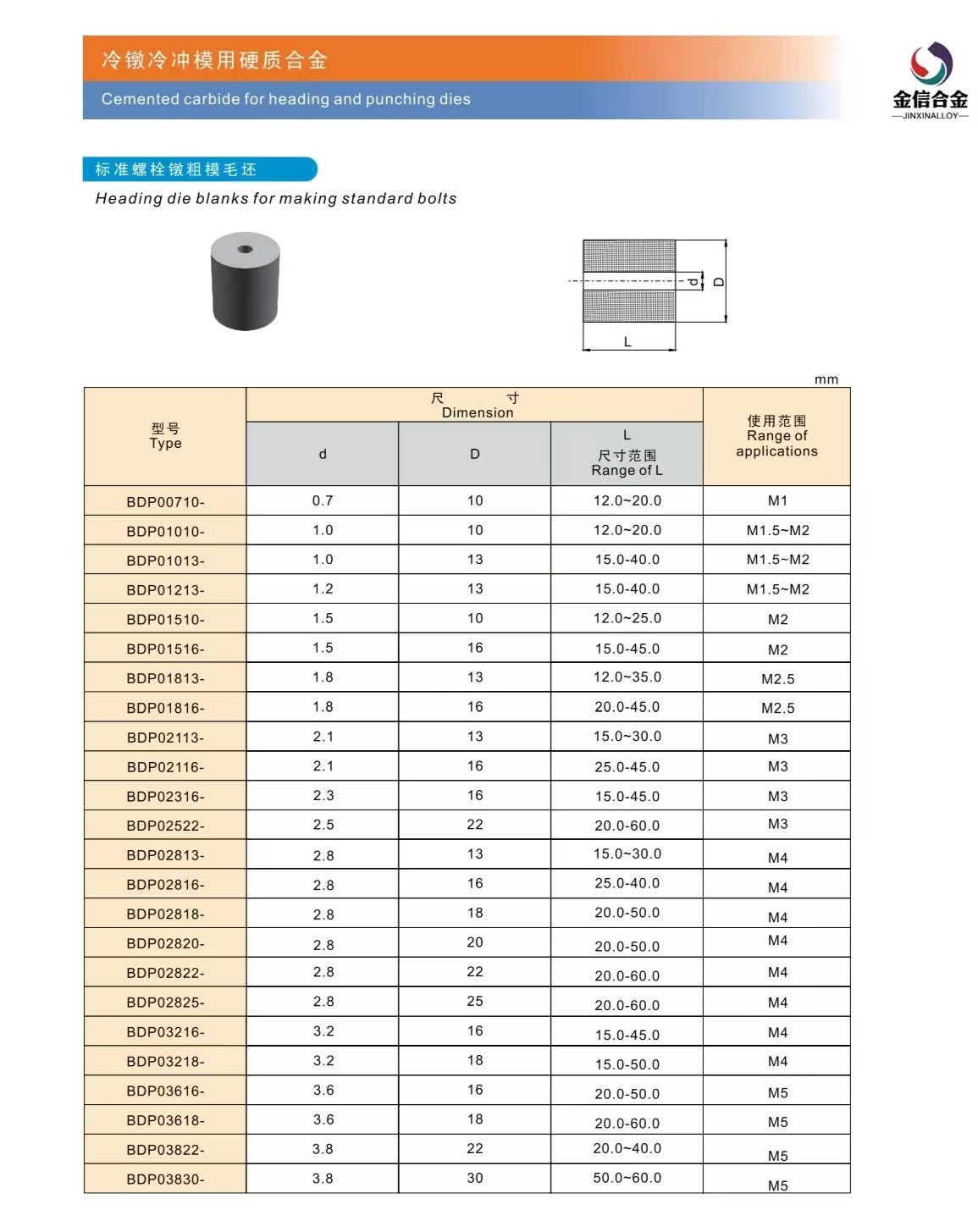

wear resistant carbide cold stamping dies for auto bolts, punching for carriage bolts

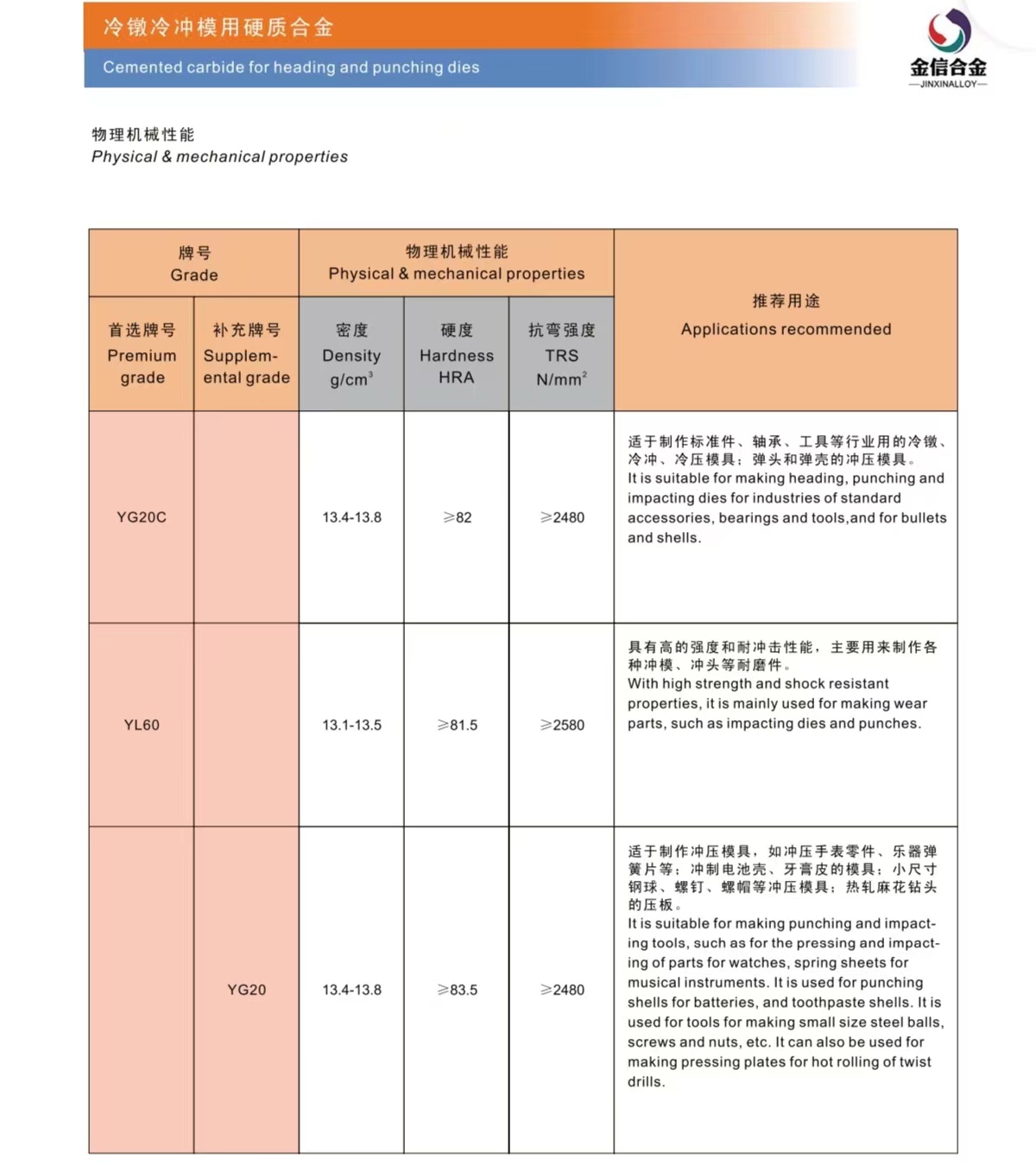

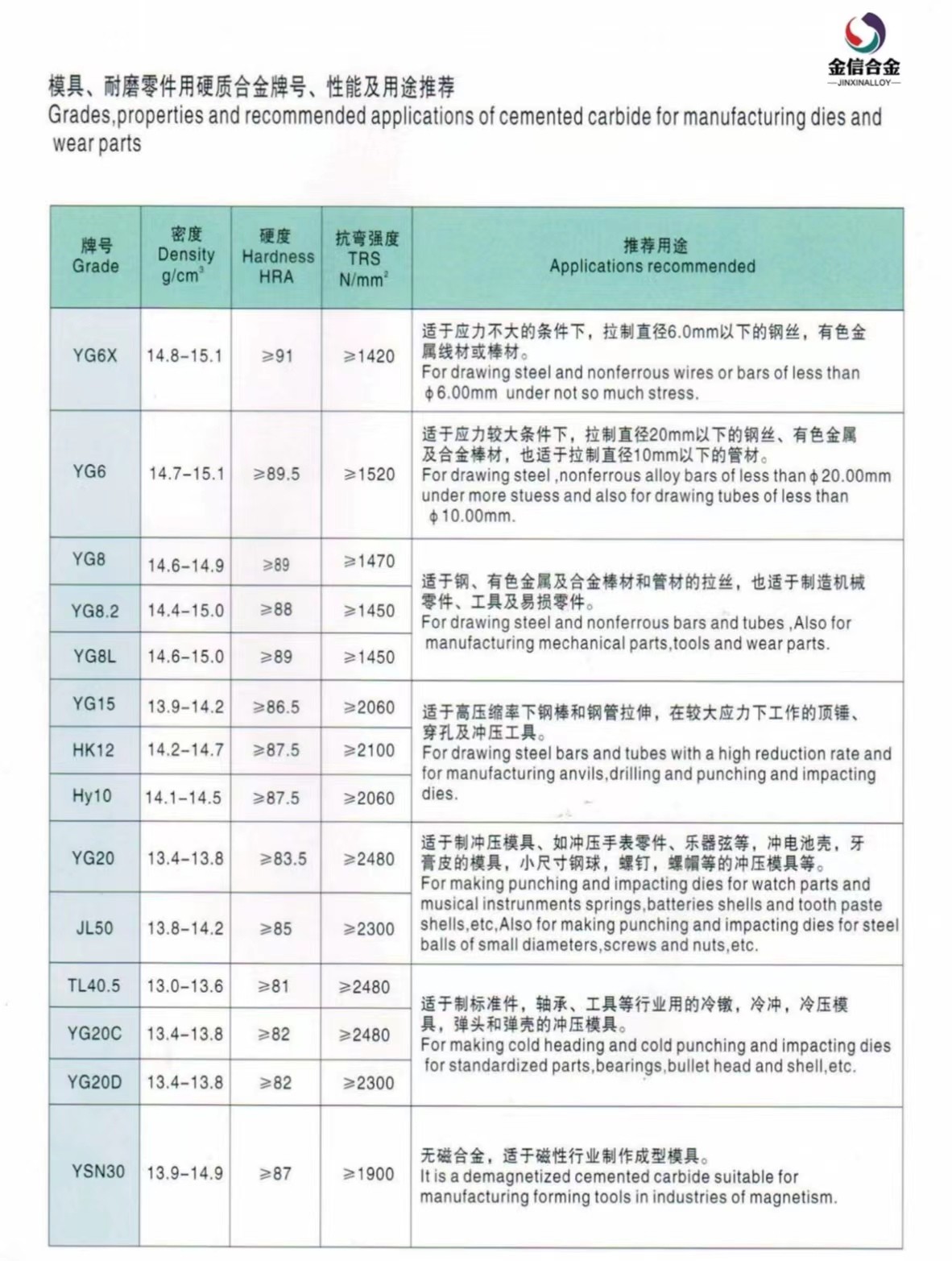

Grade | ISO | Density | TRS | Harness | Applications |

YG11C | K40 | 14.35 | 2200 | 87.6 | Forming or stamping dies for metal powders and nonmetal powders. |

YG15 | K40 | 14.0 | 2300 | 86.5 | For fabricating drawing dies of steel tubes and rods under high compressibility ratio;punchingstampingforging tools under large stress. |

YG15C | K40 | 14.0 | 2500 | 85 | |

YG18C | K40 | 13.7 | 2700 | 84.5 | Impact resistance forging dies,hot-press forging dies and rollers. |

YG20 | K40 | 13.5 | 2400 | 4 | For various dies made by cold forging,cold stamping and hot forging. |

YG20C | K40 | 13.4 | 2600 | 81-82 | Dies for wear resistant or impact resistant application |

YM3 | K05 | 15.1 | 1400 | 92 | suitable for fnishing of cast iron and nonferrous metal |

YM6X | K10 | 14.95 | 1800 | 91.5 | the finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel |

YM6 | K15 | 14.95 | 1900 | 90.5 | suiable for the roughing of cast iron and light alloys and also for themilling of cast iron and low-alloy steel |

YM8 | K20 | 14.8 | 2200 | 89.5 | |

YW1 | M10 | 13.1 | 1600 | 91.6 | suitable for fnishing and semi-finishing of stainless steel and conventionalalloy steel |

YW2 | M20 | 13 | 1800 | 90.6 | the grade can be used for the semi-finishing of stainless steel andlow-alloy steel and it is mainly used for the machining of railway |

YT15 | P10 | 11.4 | 1600 | 91.5 | suitable for the fnishing and semi-finishing for steel and cast steel witha moderate feed rate and rather high cutting speed |

YT14 | P20 | 11.6 | 1700 | 90.8 | suitable for the fnishing and semi-finishing of steel and cast steel |

YT5 | P30 | 12.9 | 2200 | 90.5 | suitable for the heavy duty rough turning of and cast steel with a bigfeed rate at a medium and low speed under unfavorable workingconditions. |

Wear resistant carbide cold stamping dies for auto bolts, punching for carriage bolts

FAQ

Q1. Are you manufacturer or trading company ?

A: We are manufacturer of tungsten carbide products. and we have extend our equipment for hardware tool production.

Q2. Is the price Competitive?

A: Jinxin offer reliable products with good price.

Q3. Are the products High Quality?

A: Yes. Raw material will be tested before bulk production, and we will check the phys-ical properties, shape and tolerance for ensuring qualified products before shipping.

Q4. How to place an order of tungsten carbide products?

A:1. Fill your Order List in our online Inquiry System.

(Also you can directly contact our salesperson by E-mail / Skype / Whats App)

2. within 24-hours feedback when receiving your message.

Q5: How we can trust your company ?

A:We support Alibaba trade insurance , 100% products quality protection, 100% on-time shipment protection, 100% payment protection for your covered amount.

Q6: What’s your delivery time ?

A:For the normal type which we have mold it takes two weeks after receiving the

advance payment.

For the non standard which we do not have mold it takes 4 to 6 weeks when receiving

the advance payment.